Industry-news

How to use fiberglass mesh cloth!

How to use fiberglass mesh cloth!

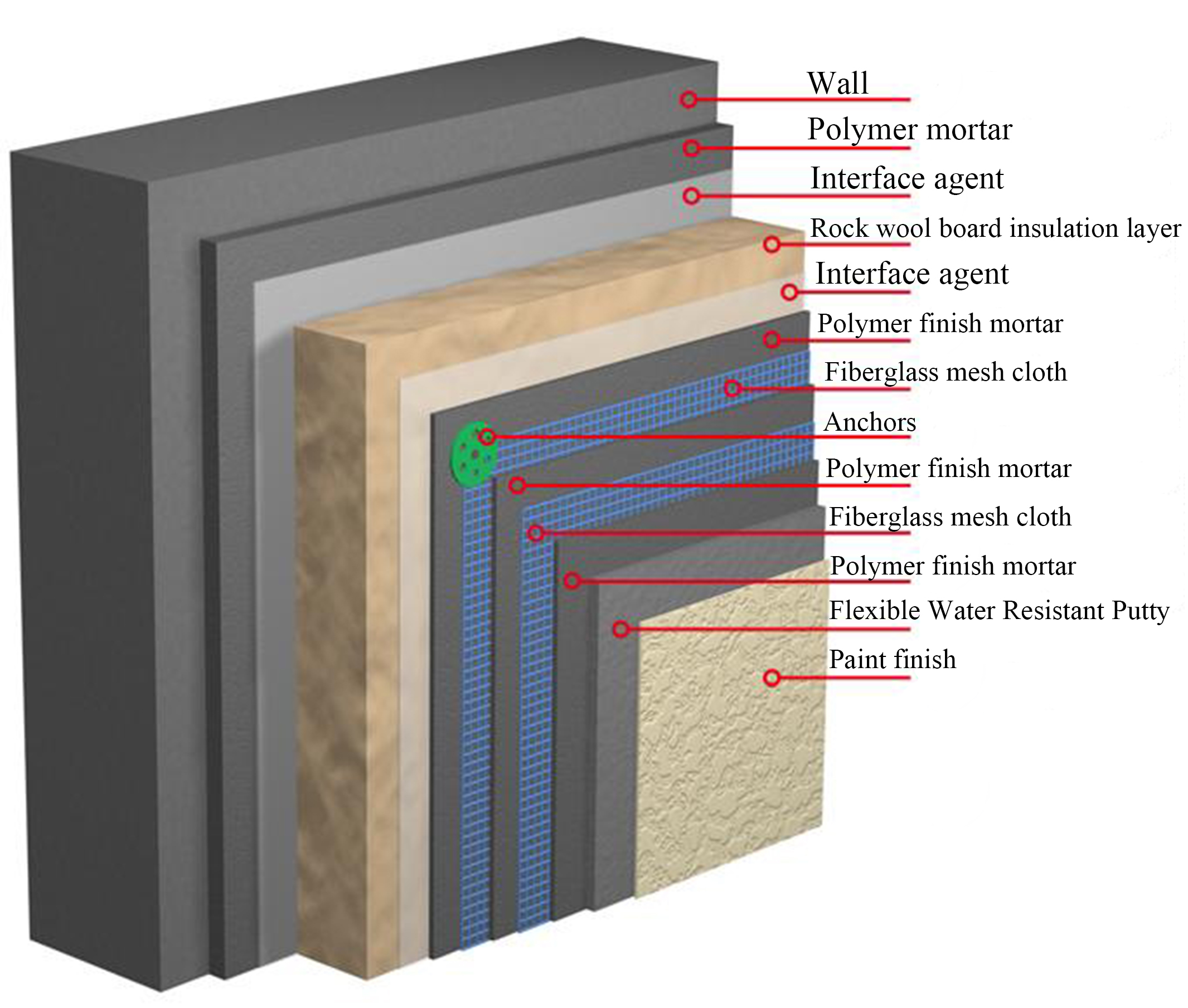

Glass fiber mesh fabric is made of glass fiber woven fabric, which is coated by polymer anti-emulsion immersion coating. So it has good alkali resistance, flexibility, as well as latitude and longitude high tensile strength, can be widely used in building walls, thermal insulation, waterproof, crack resistance. The fiberglass mesh fabric is mainly made of alkali-resistant fiberglass mesh fabric, which is made of medium alkali-free fiberglass yarn (the main component is silicate, good chemical stability) and twisted by special structure-leno weave, after high temperature heat setting treatment such as alkali-resistant liquid and reinforcing agent. The main use of glass fiber mesh fabric is widely used in wall reinforcing materials (such as glass fiber mesh, GRC wall, EPS Insulation Board, Plasterboard, waterproof membrane cloth, asphalt roof waterproof, fireproof board, construction with seam-inlaid belt and so on.

Glass fiber grid cloth paste method:

1, the preparation of polymer mortar must be responsible for special personnel to ensure the quality of mixing.

2, turn the lid counterclockwise open, with agitator or other tools to re-mix the binder, to avoid the phenomenon of binder separation, mixing moderate, so as to avoid the emergence of quality problems.

3. The ratio of polymer mortar: KL Binder: 425 # sulphoaluminate cement: Sand (with 18 mesh bottom) : = 1:1.88:3.25(weight ratio) .

4.cement, sand after weighing the bucket into the iron ash tank for mixing, stirring average proportion of binder, stirring, stirring must be average, to avoid segregation, showing gruel. Water can be added according to the workability.

5.Water for concrete.

6. polymer mortar should be used with the distribution, the best polymer mortar in 1 hour to use up. Polymer mortar should be placed in a cool place to avoid sunlight exposure.

7. Cut the mesh from the entire roll of fiberglass mesh to the desired length and width, leaving the necessary lap length or length of overlapping sections.

8. Cut in a clean and smooth place, cut material must be correct, cut mesh must be rolled up, not allowed to fold, not allowed to trample.

9. In the corner of the building to do the strengthening layer, the strengthening layer should be affixed to the innermost side, each side 150mm.

10, the first coating of polymer mortar, should keep the EPS board surface dry, remove board cotton harmful substances or impurities.

11. Scrape a layer of polymer mortar on the surface of polystyrene board, the scraped area should be slightly larger than the length or width of the mesh, the thickness should be consistent about 2mm, except for the requirement of wrapping edge, the polymer mortar should not be painted on the side of polystyrene board.

12. After scraping the polymer mortar, the mesh should be laid on it, the curved surface of the mesh facing the wall, from the center to the surrounding smear flat, so that the mesh embedded in the polymer mortar, mesh should not wrinkle, after the surface dry, then apply a layer of polymer mortar on it, the thickness of 1.0 mm, mesh should not be exposed.

13. The lap length around the mesh fabric shall not be less than 70mm, and the lap length shall not be less than 70mm at the blocked part.

14, doors and windows should be made around the shoulder strengthening layer, strengthening layer grid cloth affixed to the innermost. If the distance between the outer skin of the door and window frame and the surface of the base wall is greater than 50mm, the grid cloth and the base wall are pasted. If less than 50mm need to do turn over the package processing. The grid cloth that big metope lays should embed door window frame outside stick firmly.

15. At the four corners of the door and window, after the scale net is applied, a 200mm × 300mm scale net is added at the four corners of the door and window, which is placed at a 90-degree angle with the bisector of the window angle and pasted on the outermost side for strengthening; In the corner of a cover 200mm long, width suitable for the width of the window width of the mesh, affixed to the outermost.

16, a layer of windowsill below, in order to prevent the damage caused by impact, should be installed first reinforced mesh, and then installed scale mesh. Strengthen the mesh cloth should be docked.

17. The construction method of installing the reinforced layer is the same as the scale mesh.

18, wall pasted mesh cloth should be covered in the bag over the mesh cloth.

19, mesh from top to bottom wipe, synchronous construction of the first wipe enhanced mesh, then do scale mesh.

20, after the net should be glued to prevent rain wash or impact, easy collision angle, doors and windows should take protective measures, feed mouth area to take anti-pollution measures, surface damage or pollution must be immediately dealt with.

21, after the construction of protective layer 4 hours can not be rain.

22. Spray water in time after the final condensation of the protective layer. It shall not be less than 48 hours when the average air temperature is above 15 ° C day and night, and not less than 72 hours when it is below 15 ° C.

Ganzhou Wolfe Trading Co. , Ltd. is a large Chinese manufacturer and exporter of fiberglass and its products, our main products are fiberglass yarn, fiberglass mesh cloth, fiberglass industrial cloth, fiberglass self-adhesive tape, fiberglass fire blanket, fiberglass-covered aluminum foil self-adhesive cloth, etc. , welcome Chinese and foreign customers to negotiate procurement.

Address: Shangyou County Industrial Park, Ganzhou, Jiangxi province

Tel: 13979783338(Mr. Fang) Website:www.gzwef.com E-mail:fangyulai@163.com

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Fang

Mobile:8613979783338

Tel:8613979783338

Whatsapp:8613979783338

Email:fangyulai@163.com

Add:North Industrial Park, Shangyou County, Ganzhou, Jiangxi,China